Thanks to our fleet, that allow us to satisfy the project of the clients in a few time and costs, we realize details and semi-finished products, protective panels, tailor-made plates and shaped parts made with laser cut or plasma cutting.

OUR PROCESSES

Press bending

Press bending is a process of bending of a metal sheet using a press machinery.

It can be made in two different way: press blending on air or coining.

We can do inclined folds and folds with different angles.

Thanks to the versatility of the press blending machinery and to our experience gained, we realize lot of types of shapes, building also customized molds to realize specific projects that, usually, are impossible or so hard to be realized with the normal press bending.

Laser cut

For details in which precision is essential we use the laser cut: we can realize metal sheets with specific shapes, starting from your projects. The biggest size that we can manage is 2000x4000 mm.

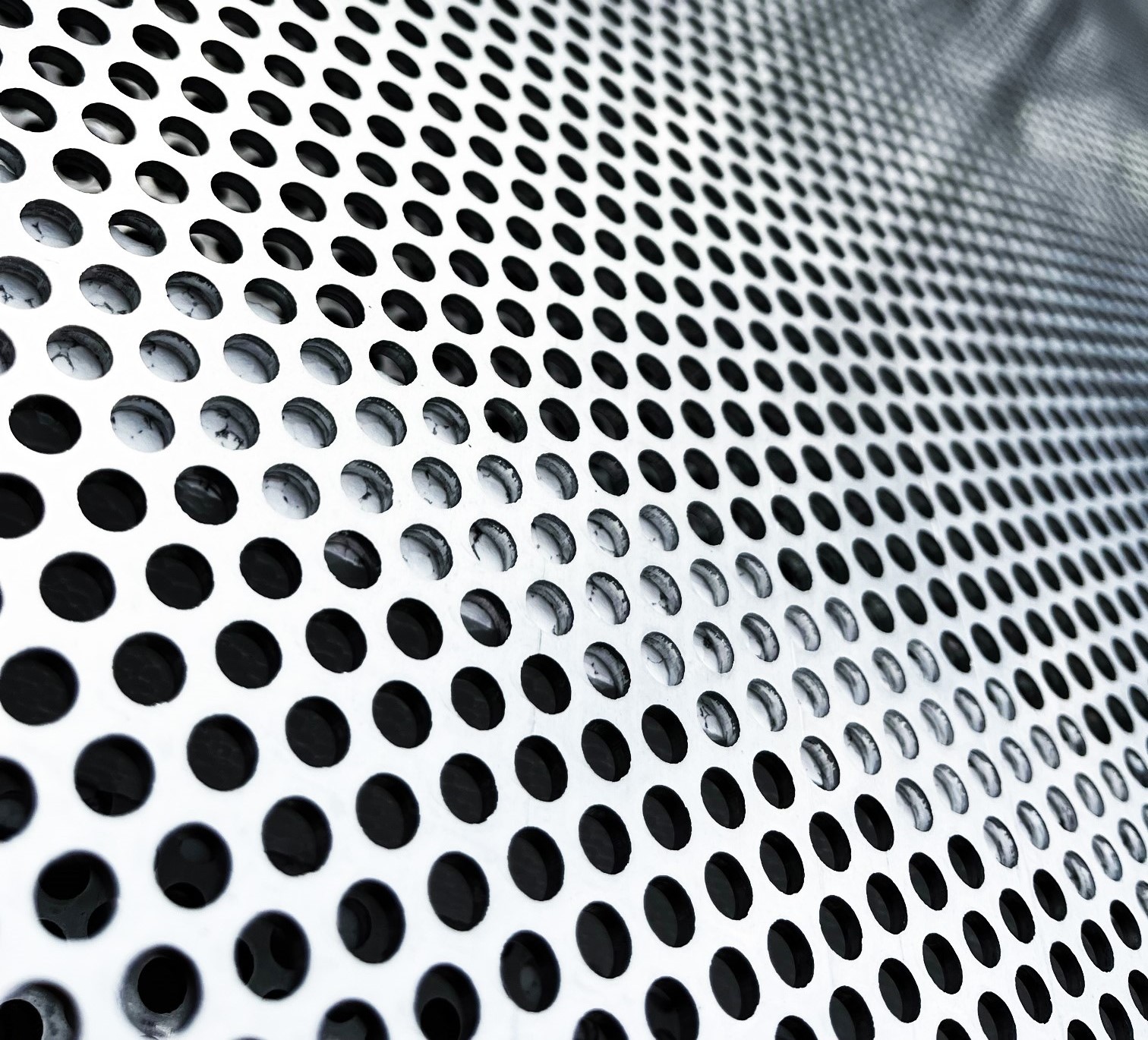

Punching

Using a punch machinery, mono-punch or pluri-punch, we can realize costumed metal sheets with holes and costumized outer edges, fixing holes and holes in a lot of different shapes and sizes.

Those types of machinery allow us to get more versatility, reducing the costs on the base of the project of the clients.

Shearing

We realize,with shearing, costumized metal sheets with guillotine shears long up to 4000 mm;

plates with cut-off automatic or semiautomatic machinery or disk saws with numerical control.

Contact us to get more informations about our equipment and our processing. Ask for a customized quote without commitment!